Facilities

Jigging Plating

Jigging is essentially the method in which parts are suspended during the process. This serves a dual process as a jig not only holds the component, but being metallic will also provide electrical contact. If there is not a natural place in which the jig can hold the component, then this may leave a witness mark after the metal finishing process has occurred. For large sized components, for example Gaskets, Silchrome may develop specialist jigs and fixtures in order to obtain the best finishing results.

Barrel Plating

Barrel Plating is typically used to process a high number of smaller sized components. The barrel contains centreboards which conduct the electrical current, and is immersed into an electrolytic plating solution. The barrel slowly rotates, causing the components to tumble or cascade thus providing an even, uniform coating. This is typically used for components such as stampings or fasteners, but may not always be suitable as certain parts such as washers which have a tendency to stick together.

Racking Plating

Rack Plating is typically used on components that are larger in size, complex in nature or are more fragile than say Nuts and Bolts. Components are affixed to metal racks which are then immersed into the plating solution, remaining static in the process. The amount of components we can rack plate at any one time depends on the process that is selected, the size of the parts and their geometry.

Dosing System

Chemical dosing system is widely applied in corrosion, scale inhibition, sterilization and algae removal of the circuiting water systems such as air-conditioning cooling water, chilled water, ice storage, etc. The chemical dosing system can also achieve the effect equivalent to the electronic descaling instrument.

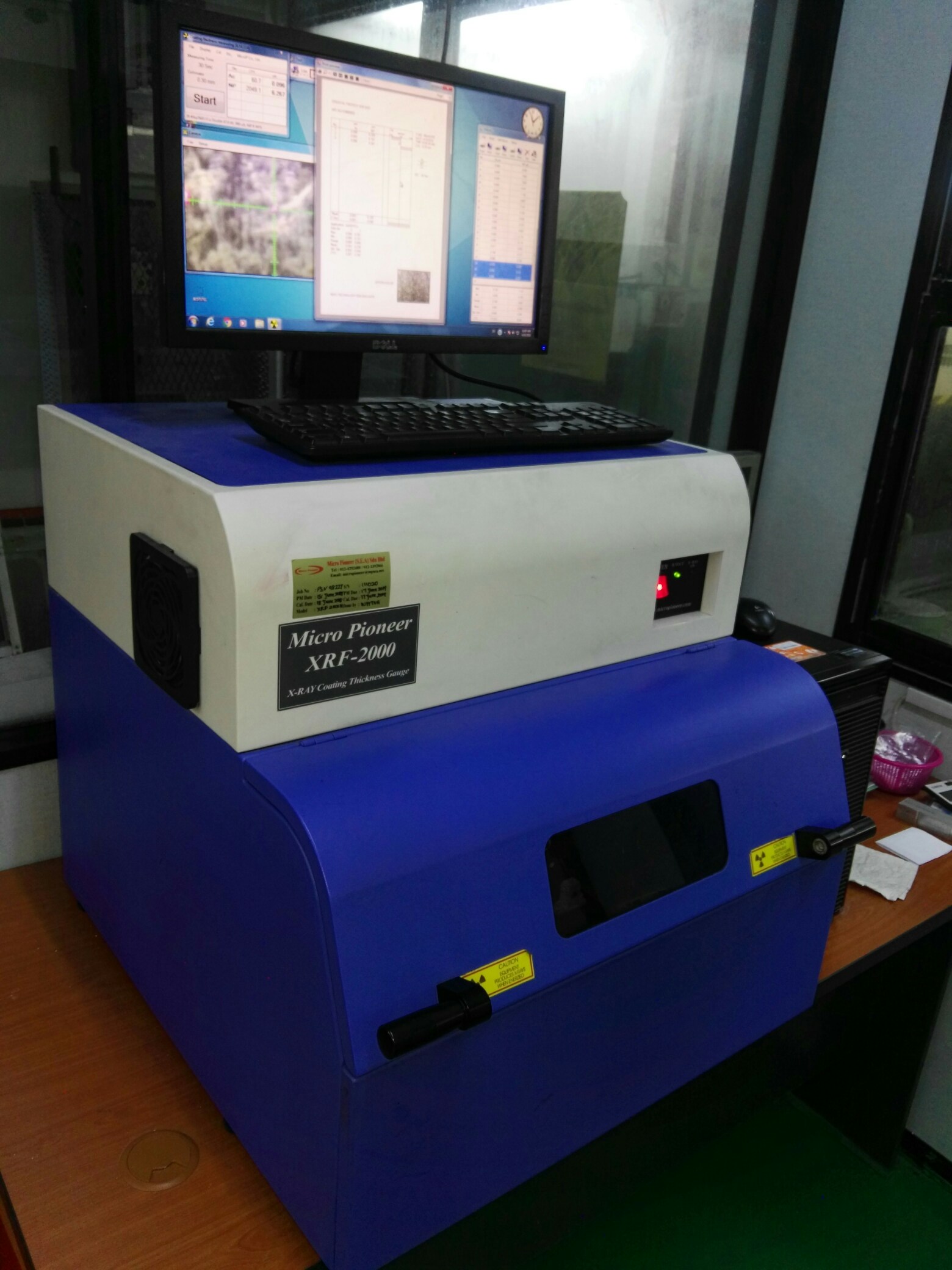

XRF Machine

To ensure the quality of our service, the XRF machine is available in our lab. XRF (X-ray fluorescence) is a non-destructive analytical technique used to determine the elemental composition of materials. XRF analyzers determine the chemistry of a sample by measuring the fluorescent (or secondary) X-ray emitted from a sample when it is excited by a primary X-ray source. The XRF machine is to run out the process of thickness inspection, making sure that we can fulfill our customers expectation.

Salt Spray Chamber

The perform method of the inspection is based on ASTM B117. The salt spray test is a standardized and popular corrosion test method, used to check corrosion resistance of materials and surface coatings. Usually, the materials to be tested are metallic and finished with a surface coating which is intended to provide a degree of corrosion protection to the underlying metal.

Waste Water Treatment Plant

Wastewater treatment is the process of converting wastewater - water that is no longer needed or is no longer suitable for use – into bilge water that can be discharged back into the environment. The treatment aims at reducing the contaminants to acceptable levels to make the water safe for discharge back into the environment. Our chemical waste water treatment plant has the capacity of 5.0 m³/hour and 4 nano sum pit (Acid, Alk, Cn & Equalization sump). The system includes the CN Destruction Tank, pH Adjustment Tank, Coagulant Tank, Flocculation Tank, Clarifier, Final pH Adjustment Tank, Sludge Holding Tank, Filter Press, Activated Carbon Filter, and the Control Panel.

Scrubber System

The Miho Technology Sdn Bhd are very concerned on our environment and the workers health. Scrubber systems are a diverse group of air pollution control devices that can be used to remove some particulates and gases from industrial exhaust streams. The scrubber system is aimed to remove harmful particles gases in the specified working environment.